News & Insights

LED Curing Technology

From our LED Technology Lab, our team of engineers develop Curing Solutions for MedTech manufacturing. We have a production-ready solution flexible to your needs.

What is LED Curing?

LED Curing is the process by which Light Emitting Diodes are used to cure materials such as adhesives, coatings, and inks. The LED Light initiates the curing process by starting a photochemical reaction which causes the linking of polymers in the material to be cured.

LED Curing has some similarities to traditional Fluorescent Light curing. However, fluorescent light bulbs emit a broad range of light wavelength, an LED can be selected to suit the precise wavelength that best suits material to be cured. LED technology provides some significant advantages which include:

- Specific wavelength

- Greater uniformity of light throughout the cure tunnel

- Automatic fault detection

- Energy efficiency

- Environmentally friendly

Our Experience in LED Curing

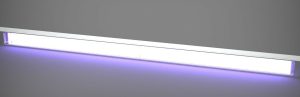

After extensive research and development in our LED Technology Lab, we have designed and built our own LED Tube Technology, currently being used by blue-chip manufacturers in the medical device sector.

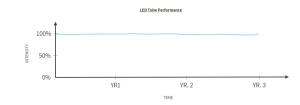

The testing and development of our LED technology involved the continuous operation of the LED tubes 24 hours a day, 7 days a week over the course of 3 years in a replicated automated production environment. Even operating inside a controlled high-temperature environment resulted in no deterioration of LED performance.

Advantages of Our LED Curing Technology

Low Cost of Ownership

Our LED Curing Technology is highly efficient offering vastly improved lifetimes with a minimum life expectancy of 5 years, reduced maintenance costs and significant energy savings.

Reliable Performance in High-Temperature Environments

After extensive testing and development, our LED Technology is proven to operate in high-temperature environments.

A Safe, Clean, Environmentally Friendly Solution

Traditional Fluorescent UV bulbs used in Curing processes contain mercury, which is toxic to people and the environment, and is costly to dispose of. Our LED technology is a safer, sustainable alternative, using less energy and producing less heat, while offering higher performance.

A Smart, Intelligent Solution

Our LED technology enable intelligent feedback and fault detection capability.

The solution is integration friendly and can connect to modern production equipment over a variety of BUS type networks such as Ethernet & Profibus.

Why Choose Us as Your Partner?

A Reliable, Production-Ready Solution

Accelerated testing of our LED Tubes in a replicated automated production environment ensure they can operate even in high-temperature environments with a minimum life expectancy of 5-years.

A Complete Solution Provider

Our LED Curing Solutions are flexible and configurable to your needs and requirements.

Our experience as one of the largest automation builders in Europe allows us to integrate our LED Curing Technology into a fully custom-built automated manufacturing line.

Seamless Installation & Ease of Use

Our LED tubes are designed for a quick change out mechanically and electrically including network communication to minimise the installation and swap out effort required.